The global automotive industry with a history of one hundred years is in a period of great changes in which various technologies and innovative applications are emerging one after another. New energy, intelligent interconnection and autonomous driving have become the main trends in the future development of the automotive industry. The global automotive industry is undergoing a full range of changes and innovations, ushering in unprecedented opportunities and challenges, and the various parts and components that make up the car are the basic carriers that lead its changes and innovations.

Looking at the current auto parts industry, there are mainly four major development trends:

1. Global procurement

In the context of globalization, in the face of increasingly fierce competition, the world's major automobile companies have gradually reduced the self-manufacturing rate of auto parts while expanding their production scale in order to reduce costs, adopting a global procurement strategy for parts. At the same time, in order to obtain greater benefits, international component suppliers reduce or even stop the production of some of their products that do not have a competitive advantage, and instead purchase products with comparative advantages globally.

2. System matching and modular supply gradually rise

Increasingly fierce market competition is forcing vehicle manufacturers to switch from purchasing individual parts to purchasing entire systems. This change not only helps vehicle manufacturers make full use of the professional advantages of parts and components companies, but also simplifies product matching links and shortens the new product development cycle. As system suppliers increasingly participate in the R&D, design, and production processes of vehicle manufacturers' new products, their technical and economic strength is gradually becoming stronger. The system support has given birth to the modular supply of parts and components companies. In the modular supply, the parts and components companies undertake more development of new products and new technologies. The vehicle manufacturers are increasingly relying on the parts and components companies in terms of products and technologies. The status of component companies in the automotive industry is becoming more and more important.

3. Accelerating industrial transfer

The high labor costs in developed countries such as Europe, America and Japan have led to the lack of cost advantages for auto parts and components produced in these countries. In response to market competition, the large auto parts companies in the above-mentioned countries have accelerated the speed of industrial transfer. They have not only transferred production and manufacturing links to low-cost countries and regions on a large scale, but also gradually extended the scope of transfer to research and development, design, procurement, sales and after-sales service. The scale of the transfer is getting bigger and bigger, and the level is getting higher and higher. Countries such as China and India have become the main destinations that attract the transfer of the global auto parts industry.

4. Market share of dominant companies is becoming more concentrated

In the context of increasingly detailed division of labor, vehicle manufacturers have shifted from a traditional vertical operation, pursuing large and comprehensive production mode to a streamlined organization and specialized production mode focusing on the development of complete vehicle projects. The industry has formed a pyramid structure of multi-level division of labor, such as Tier One component suppliers, Tier Two component suppliers, and Tier Three component suppliers. Generally speaking, the lower the level, the greater the number of suppliers at that level. However, the current large-scale grouping of parts manufacturing enterprises has gradually led to corresponding changes in the structure between vehicle manufacturers and Tier One parts suppliers, and the number of Tier One parts suppliers is constantly decreasing. With the continuous deepening of the grouping of parts and components companies, the automobile industry has increasingly formed a structure in which a few parts and components companies monopolize the production of certain parts and provide them to many vehicle manufacturers.

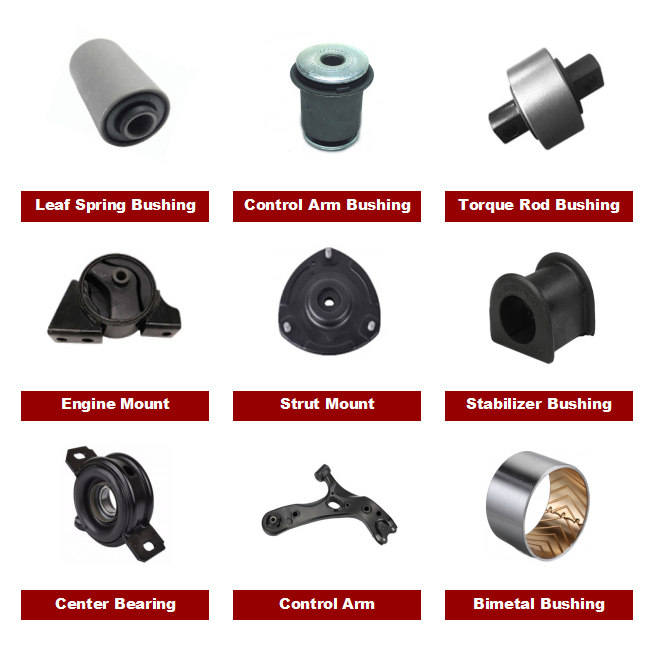

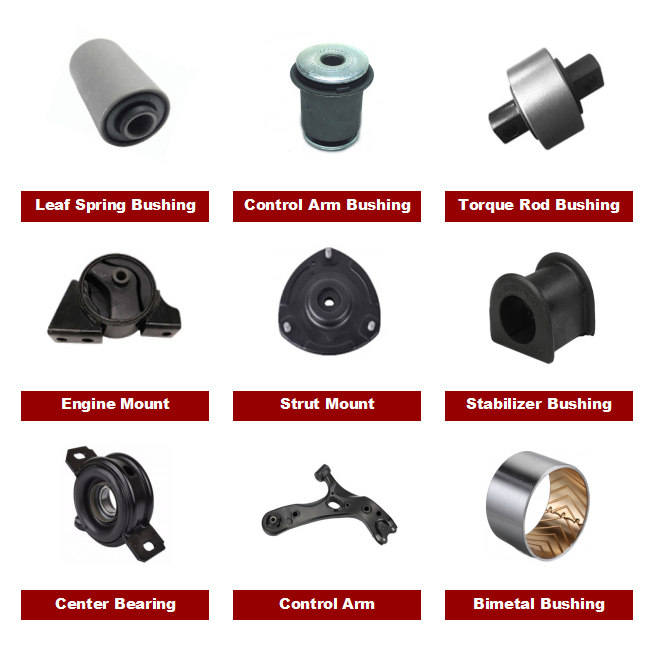

GJ Bush factory serves for many overseas and domestic OEM customers, which with over 20 years research and development experience for manufacturing automotive suspension rubber parts, especially in rubber bush and rubber mount products. We will keep our faith and go further and further!