What Are Shock Absorber?

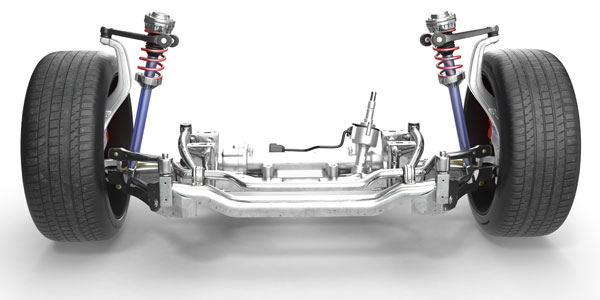

Shock absorbers are vital components of a vehicle's suspension system, playing a crucial role in ensuring a smooth and comfortable ride. These ingenious devices effectively dampen the vibrations and oscillations arising from uneven road surfaces, potholes, or sudden maneuvers. Employing a combination of hydraulic fluid dynamics and mechanical engineering principles, shock absorbers absorb kinetic energy generated by the vehicle's vertical motion and convert it into heat energy that is dissipated into the atmosphere. By doing so, they attenuate excessive bouncing or jolting motions that would otherwise transmit directly to the chassis and passengers.

This not only enhances driving comfort but also contributes significantly to safety on roads as it allows for improved traction between tires and pavement during critical moments. The design intricacies within shock absorbers ensure precise control over damping forces according to various driving conditions while maintaining stability under different load capacities. Filled with specialized fluids such as silicone oil or gas chambers containing nitrogen, these mechanisms consistently adapt their behavior to optimize ride quality without compromising steering responsiveness or overall handling characteristics. In summary, shock absorbers embody an amalgamation of advanced engineering concepts aimed at providing motorists with enhanced ride comfort, safety assurance, optimal handling capabilities across diverse terrain types while minimizing fatigue induced by rough road conditions on both driver and passengers alike.

Causes Of Shock Absorber Failures

Shock absorbers play a crucial role in ensuring a smooth and comfortable ride for your vehicle. However, as with all components, they are subject to wear and tear and can eventually break. The question is, why do shock absorbers break? Is it due to poor quality materials, or inadequate maintenance? We will explore the main causes of shock absorber failures and provide some practical advice on how to prevent them from happening. Understanding the reasons behind shock absorber breakdowns can help you make informed decisions when it comes to replacing them and ensure your car handles well, no matter the driving conditions. We'll discuss issues such as overuse, failed seals, and corrosion and explain how each of these can lead to shock absorber failure. Additionally, we'll look at what symptoms you should watch out for that indicate a problem with your shock absorbers and consider how neglecting them can impact other parts of your car.

1. Worn out bushings

One of the most common reasons as to why shock absorbers break is worn out bushings. The purpose of bushings is to provide a cushion between the mount of the shock absorber and the frame of the vehicle. Without proper cushioning, the shock absorber can take more of the impact from bumps and vibrations, leading to premature wear and tear. It's important to regularly inspect the bushings and replace them as necessary, as they can become worn over time due to constant exposure to the elements and general wear and tear. Failure to do so can lead to a decrease in ride comfort, a decrease in handling, and even in some cases, a complete failure of the shock absorber system.

2. Excessive load on the shock absorber

One of the reasons why shock absorbers break is due to excessive load on the shock absorber. This can happen when the vehicle is overloaded with passengers and cargo beyond the recommended weight limit. When the weight exceeds the limit, it puts undue strain on the shock absorber and can cause it to wear out quickly. The shock absorber's function is to control the vehicle's movements and ensure a smooth and comfortable ride. When the load is too much for the shock absorber to handle, it can fail to perform effectively, leading to issues such as reduced handling, increased stopping distance, and uneven tire wear. Therefore, it is crucial to observe the recommended weight limits and not overload the vehicle to avoid damaging the shock absorber.

3. Misalignment of the suspension

One of the reasons why shock absorbers break is the misalignment of the suspension. When the suspension is not aligned properly, it can put excessive stress on the shock absorbers. This stress can cause the shock absorbers to wear down and eventually fail. Misalignment can occur due to various reasons such as contact with curbs, potholes, or other obstacles on the road. Moreover, aftermarket modifications and incorrect installation of parts can also lead to misalignment. Regular inspection of the suspension system and addressing misalignment issues can prolong the life of shock absorbers and prevent sudden failures that can compromise vehicle safety. Therefore, it is essential to ensure proper alignment of the suspension for a smooth and safe driving experience.

4. Corrosion of parts due to moisture

Moisture can be a significant factor contributing to the breakdown of shock absorbers. The presence of moisture leads to corrosion of metal parts, which, in turn, weakens the structural integrity of the shock absorbers. Moisture can enter the shock absorbers from different sources, such as humidity in the air or water that splashes on the car while driving through puddles, among others. The corrosion process may go unnoticed until it has already caused damage, which can lead to premature failure of the shock absorbers. To minimize corrosion effects, regular inspections and preventive maintenance can help identify potential issues before they escalate. Additionally, using high-quality materials and protective coatings that are resistant to moisture can also help extend the lifespan of shock absorbers.

5. Damage due to road debris

Damage due to road debris is a common cause of shock absorber failure. The wear and tear on the suspension system from debris can cause the shock absorber to become damaged and lose its effectiveness over time. Rocks, gravel, and other road debris can cause punctures or tears in the shock absorber cylinder or piston, which may lead to fluid leakage. This can cause the shock absorber to become less responsive and less effective at absorbing the impact of bumps and potholes on the road. It is important to regularly inspect the shock absorbers for any signs of damage caused by road debris, and replace them as necessary to ensure optimal performance and safety while driving.

Conclusion

In short, shock absorbers play a vital role in keeping the car's ride smooth and stable. There may be various reasons contributing to their breakage, such as overuse, wear and tear, corrosion, and more. It is essential to note that ignoring such symptoms may lead to more significant issues in the long run, such as tire wear, wheel alignment problems, and decreased braking efficiency. Therefore, it is best to keep an eye on the suspension system's functions and replace any damaged or malfunctioning parts immediately to ensure your safety while driving. Welcome to contact GYCX shock absorber supplier!

Copyright © 2025 GYCX Factory | All Rights Reserved.