How to go through the bi-metal bushing customization?

2021-04-27

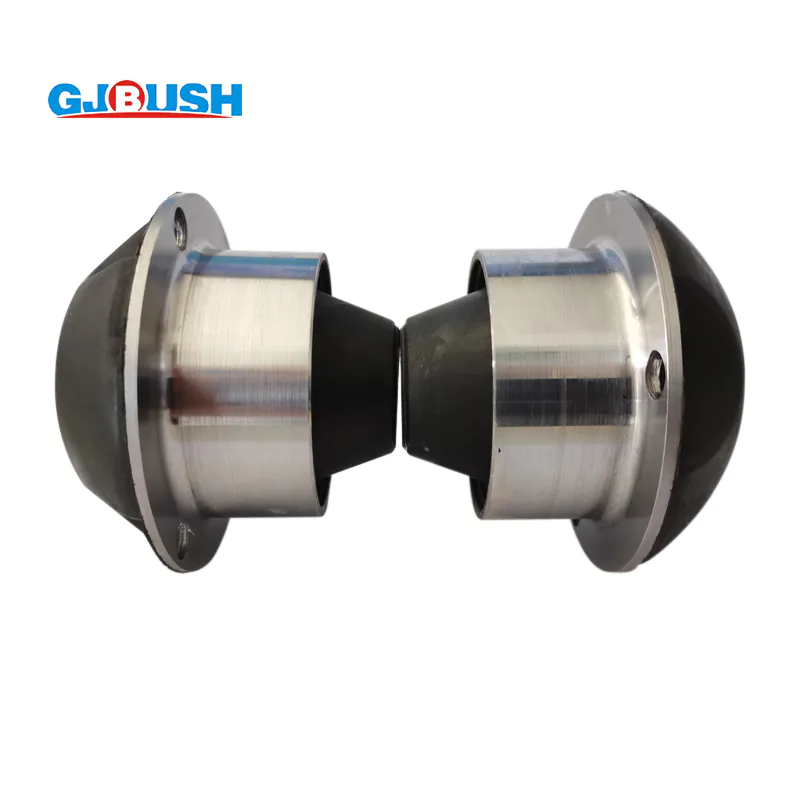

For the detailed requirements put forward by customers, we first need to analyze the possibility and feasibility of bi-metal bushing customization considering its possible target industry and performance change. After completing this analysis process, we are able to give a detailed answer to this question. Then, customers need to submit your requirements like sizes change, logo printing, or name design. Once our innovative designers finish working out the product sketches or CAD drawings, we will send them immediately to you for confirmations. The next step goes to sample making. Once customers are assured of and satisfied with the sample, producing in mass will start according to the order queue.

Nanchang Ganjiang Bush Factory has a focus on the design and production of rubber mounting. Over the years, we have gained a wealth of experience. leaf spring bush is one of GJ Bush's multiple product series. Digital molding technique and meta-mechanical analysis are used in the development of GJ Bush engine mount bracket by the R&D team. The team strives to create a product with high precision which suits most people's foot arch. GJ Bush is proud to provide premium quality OEM grade auto parts for over 20 years. The product is well received by customers for its high performance and durability.

In the rubber bushing shock absorber industry, the our team brand will pay more attention to service quality. Welcome to visit our factory!

Nanchang Ganjiang Bush Factory has a focus on the design and production of rubber mounting. Over the years, we have gained a wealth of experience. leaf spring bush is one of GJ Bush's multiple product series. Digital molding technique and meta-mechanical analysis are used in the development of GJ Bush engine mount bracket by the R&D team. The team strives to create a product with high precision which suits most people's foot arch. GJ Bush is proud to provide premium quality OEM grade auto parts for over 20 years. The product is well received by customers for its high performance and durability.

In the rubber bushing shock absorber industry, the our team brand will pay more attention to service quality. Welcome to visit our factory!

Custom message