The control arm is the guiding and force transmission element of the automobile suspension system. It transmits various forces acting on the wheels to the car body while ensuring that the wheels move according to a certain trajectory. The control arm connects the wheel and the vehicle body elastically through a ball head or a bushing respectively. The control arm (including the bushing and ball head connected to it) has sufficient rigidity, strength and service life.

When the car is driving, every time it vibrates up and down, the suspension system will make a "chucking" sound. When the road is uneven, the sound will increase. When turning, the body tilts too much, indicating the shock absorber, stabilizer bar, or guiding mechanism If the component is damaged, it means that the suspension system is malfunctioning, which may be due to damage to the shock absorber or damage to the shock absorber rubber sleeve.

All cars will have wear items after used for a certain period of time. When the service life of the vehicle reaches 100-120K miles of driving range, most suspension bushings and joints will experience excessive wear or cracking. Many of these come in the form of bushings or joints. Although modern technology has greatly improved the service life of these components, they will eventually need to be replaced.

Replacing these items is a relatively simple process, and there are some tips to help you complete it quickly. The bushing consists of three parts, the outer shell, the rubber or polyurethane bushing and the inner sleeve. If the rubber is cracked or the inner and outer jacket is rusted, this can make them difficult to remove. There are several ways to do it.

Manual removal

This is a more difficult method to remove the control arm bushing. Usually only need to use a hammer to hit the control arm bushing, which can easily damage the arm itself.

Tooling method

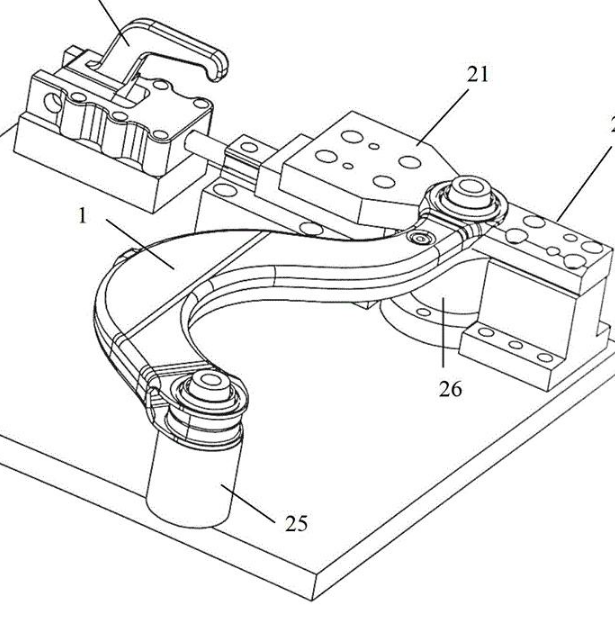

Use a tooling to press, choose a driver that matches the shell of the control arm bushing, and then slowly drive the control arm bushing out. Perform the reverse operation to install a new bushing.

Hydraulic press method

This is the easiest and fastest way to remove and install the control arm bushing. A thread press can be used to perform this operation.

The key to all these processes is to ensure that the control arm is not damaged, especially in the stamped steel arm, if it hits the edge of the control arm instead of the bushing shell, it may be crushed. It takes a lot of labor to replace the control arm bushing, but it should be done immediately with the correct tools.

If you have any needs or questions about automotive suspension parts, please contact us. GJ BUSH factory is a professional OEM rubber bushing manufacturer.

Copyright © 2025 GYCX Factory | All Rights Reserved.