With the continuous development of my country's social economy, the popularity of automobiles has soared; while the sales of automobiles have surged, the automobile industry has ushered in a spring of vigorous development. At the same time, consumers in the automobile market have gradually increased the quality requirements of automobile products. When consumers choose automobiles, stability and durability have become an important selection criterion. The stable and sustainable development of the automobile industry is of great significance and impetus to my country's economic development strategy, which requires the automobile production industry to strictly control the quality of parts and complete machines, and improve automobile quality control.

Development of Quality Control Theory in Automobile and Parts Manufacturing

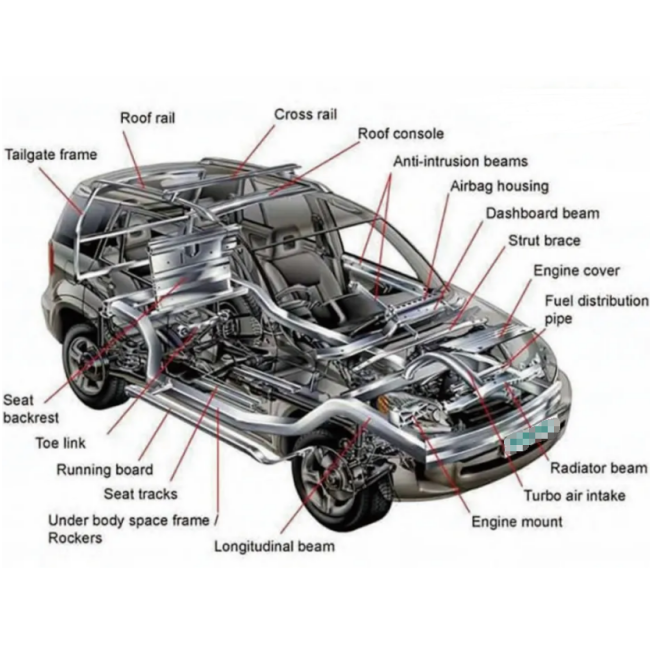

A car is assembled from thousands of parts, ranging from a bolt to an entire engine. Every part plays a vital role in improving the quality of the whole vehicle. The first thing to do is to improve the quality of the parts. . Currently, Chinese automakers subcontract many parts to corresponding manufacturers to achieve co-production. In this production relationship, the product quality and quality control of the component manufacturer directly determine the quality of the entire vehicle product. In this production process, product quality control can be divided into quality inspection stage, statistical quality control stage and total quality management stage. Among them, quality inspection is an active control method for the quality of auto parts. According to the characteristics of parts and production processes, corresponding quality inspection measures are established to realize active control of product quality.

Measures for quality control of auto parts

Strengthen Quality Management in Manufacturing Links

Quality inspection under the supervision of production technology is very important. There are many types and quantities of auto parts. The same auto parts use different materials, manufacturing equipment, processing technology and process control, and use requirements are also different, which leads to the complexity of auto parts manufacturing and management. To ensure that enterprises can produce high-quality auto parts, advanced manufacturing processes and equipment should be adopted, and the application level of technology and manufacturing personnel to equipment and processes should be improved. At present, my country's auto parts manufacturing generally adopts numerical control equipment, which is highly automated and suitable for mass manufacturing. If the advanced intelligent manufacturing technology is further adopted, only the operation program needs to be replaced, and the operation is more convenient. One person can be responsible for multiple devices at the same time, which can effectively improve the manufacturing efficiency of the enterprise, and can control the software control program for the first time. The deviation is corrected, which greatly improves the precision and consistency of auto parts processing. At the same time, in each link of manufacturing, the inspection of semi-finished products and finished products should be strengthened to ensure that the products of each process meet the quality requirements.

The improvement of personnel skills and the cultivation of quality awareness are conducive to eliminating hidden quality risks

At present, most equipment operators still rely on people. With the development of the domestic automobile industry, the demand for personnel of various parts and components enterprises has increased. Due to the lack of self-reserve personnel, a large number of external personnel with certain operating skills and automotive industry technicians will be recruited. However, in order to complete orders, enterprises lack periodic training, resulting in It happens from time to time to blindly go to work. In addition to reserving talents, the company should also strengthen the training of internal personnel skills, especially the production front-line employees, so that every employee is familiar with the post craft work instructions and operating skills.

At present, the car has become a mass product. The number of car users continues to increase, and the problems of cars and parts are gradually exposed. In recent years, although my country's automobile manufacturing technology has advanced by leaps and bounds, and the performance and functions of domestic automobiles have been greatly improved, the quality and quality control problems still restrict the development of my country's automobile industry. In automobile production, the quality control of automobiles and parts, We are required to reasonably use the quality control and management methods of automobiles and parts to ensure the safety and service life of automobiles.

Copyright © 2025 GYCX Factory | All Rights Reserved.