Along with the development of auto industry, automobiles plays the part of more and more important role. People requires higher to the properties of automobile especially NVH performance and reliability. Rubber bushing is a key part of the automotive chassis system for performance and safety. Bushing is made up of metal and rubber, has good absorption of high frequency vibration and isolation effect. The suspension parts are connected to each other via rubber bushings to the subsystem, During cars running, the rubber bushing is under alternating load, when rubber bushing loses its function, it has a strong influence on NVH performance and automobile comfort, and even affects dynamic and safety. Therefore, OEM plants paid much more attention to the Fatigue Test of rubber bushings.

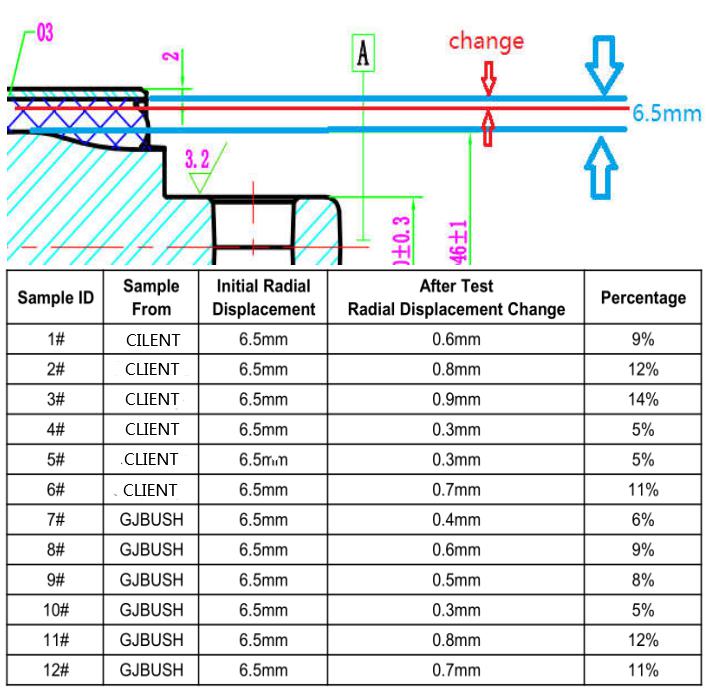

The purpose of the fatigue test is to evaluate the working life of the rubber bushing, which can be evaluated by the change in characteristics and appearance of the rubber bushing before and after the fatigue test. The test divided into real road test, skid pad test and laboratory test. The laboratory test cycle is short, the cost is low, and the control ability is good, and it has become a widely used test method at this stage.

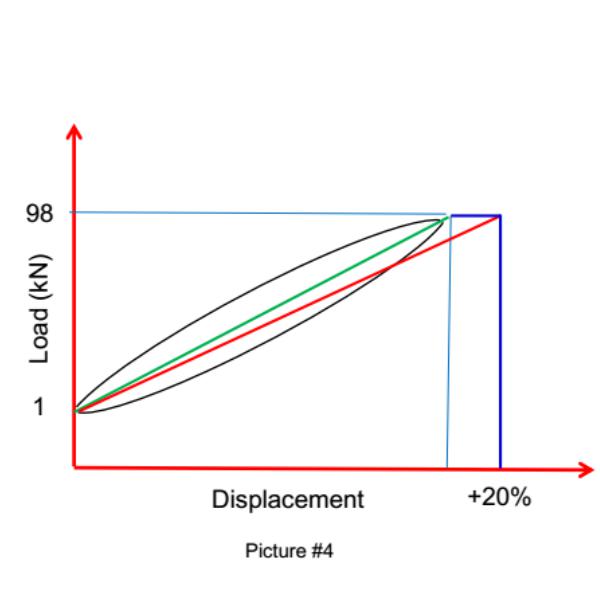

The Lab test generally uses the non-resonant method, apply alternating loads, and cyclically loaded with force. When the force and vibration reached the required number of experiments, by testing the static stiffness loss rate and cracking value of the rubber bushing before and after the experiment, it can evaluate whether the rubber bushing has fatigue failure according to the criterion of rubber bushing fatigue failure. If the test does not reach the number of required vibration frequency during the test, it can be determined that the rubber bushing sample has fatigue failure. Fatigue test should be conducted in accordance with relevant test specifications similar to the actual vehicle operating conditions, such as load, amplitude, vibration frequency and pre-pressure.

Copyright © 2025 GYCX Factory | All Rights Reserved.