Marine Engine Mount, also known as MM mount, is a rubber metal anti vibration mounts. They are usually used for internal combustion engines, gearboxes, pumps and motors, and other types of equipment on ships. Mechanical vibration and shock loads are more common in engines and electronic equipment on ships. In order to solve this problem, it is necessary to manufacture a series of anti-vibration products for ships. Marine Engine Mount will help reduce negative impacts and keep equipment running smoothly. Due to its sturdy structure, marine engine mounts are ideal for mobile applications.

Their special design provides multiple axial stiffness values, high vertical elasticity, increased longitudinal stiffness and optimal lateral stiffness to improve vibration isolation on the shaft. Some Engine Mount have different stiffness in the three main directions of loading and therefore allowing a high degree of flexibility to ensure good vibration isolation while minimizing movement on other planes.

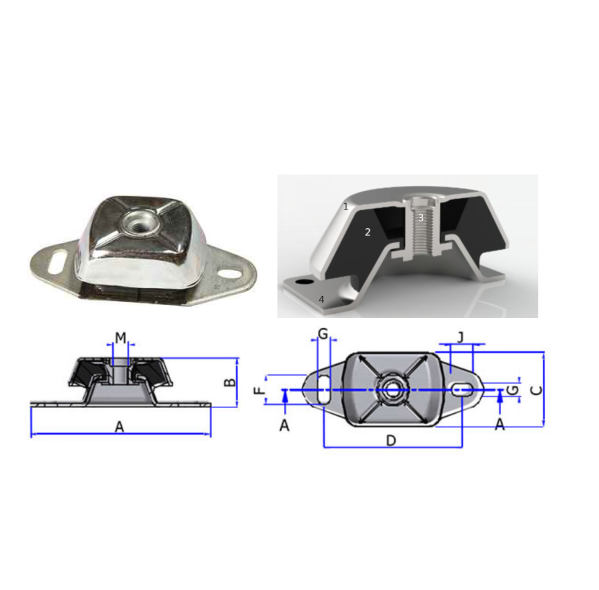

The Marine Engine Mount generally made of high-performance rubber and low-carbon steel, with standard transparent galvanized anti-rust. Use the 8.8-level height adjustment bolt to align the engine and transmission with the drive shaft without worrying about shearing the bolts. The metal cover of some Marine Engine Mount will be designed with a cross-shaped dent shape, which can enhance its rigidity in mobile applications. The metal cover can also prevent the elastomer from dripping oil inside the bracket and improve its resistance to oil or liquid splashed on it, allowing them to flow out of the bracket. All metal parts on the MM mounting seat have anti-corrosion treatment, which is suitable for demanding outdoor applications under harsh environmental conditions. When used on ships, diesel, ozone, and/or ultraviolet light can cause significant damage to rubber, so it is particularly important to use high-performance materials. Also, MM mount has interlocking metal parts to provide fail-safe protection for mobile applications. When the device is impacted, the device restricts vertical movement.

In the production process, the use of control methods to measure several key parameters, such as the control stiffness and the level of rubber-metal adhesion and other parameters, can provide traceability of product performance to ensure the quality level of the product.

Copyright © 2025 GYCX Factory | All Rights Reserved.