How are rubber bushings vulcanized

The production of rubber bushings requires multiple processes to complete. Among them, vulcanization is the most important process. So, how does the vulcanization process happen? Through this video, I believe you should have a more intuitive understanding.

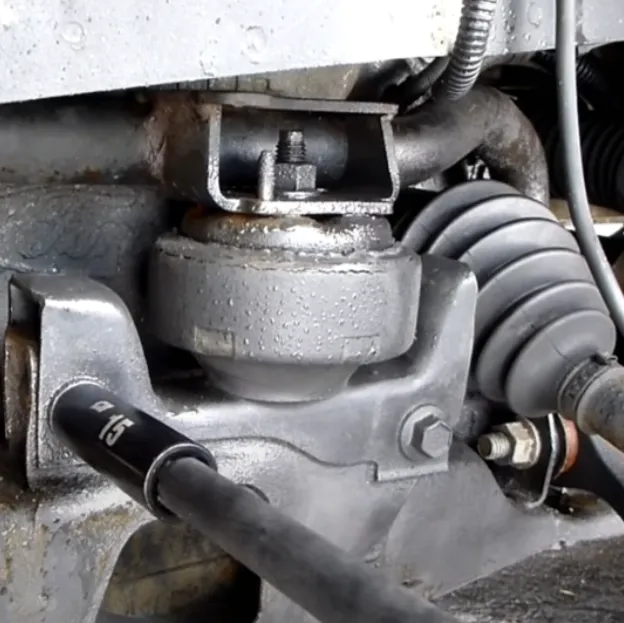

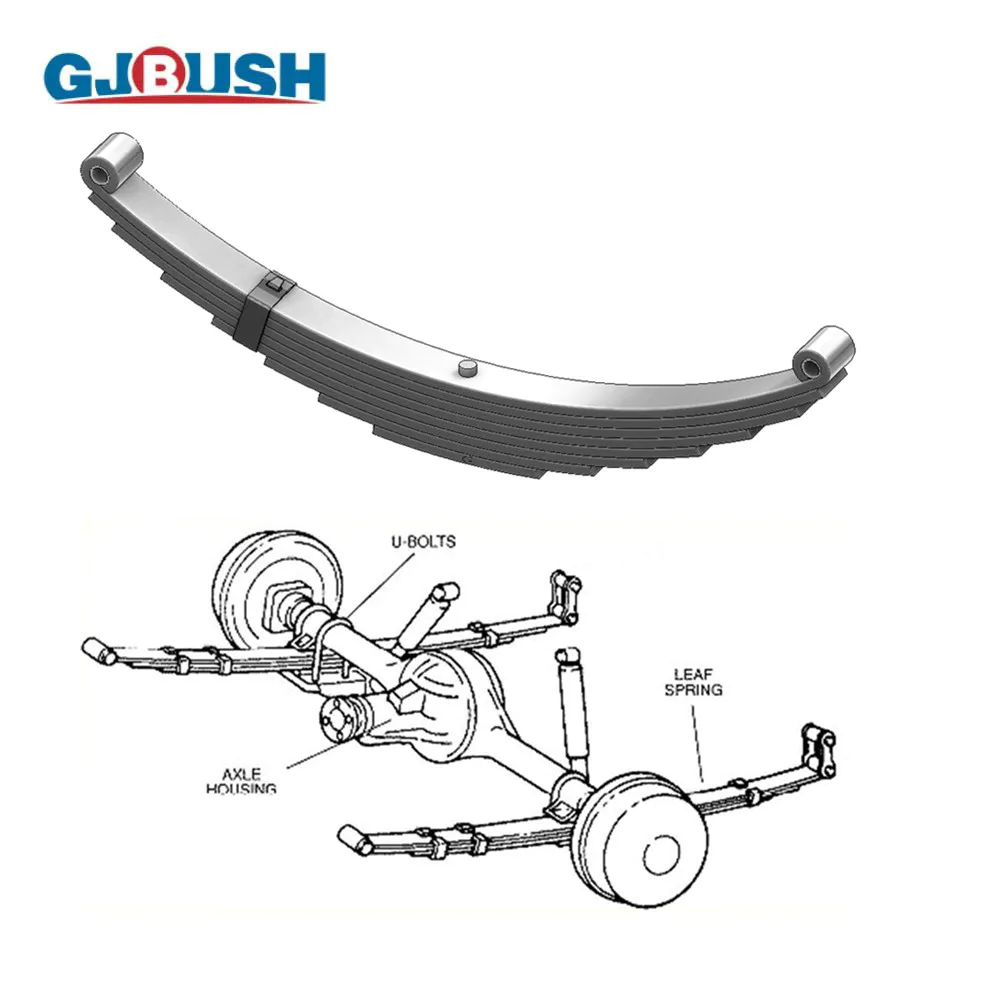

Vulcanization is a process in which raw rubber is heated and combined with other materials to create a stronger, more resilient finished product. This process was invented in the early 19th century and has since been used to produce a variety of products, including tires, hoses, and gaskets. Vulcanization strengthens rubber by creating cross-links between its molecules. Rubber bushings are one of the many products that can be made using vulcanization. These components are commonly used in automotive applications to cushion and isolate suspension components from each other and from road vibrations. Vulcanizing rubber bushings improves their durability and resistance to heat and chemicals. As a result, they are able to withstand the rigors of everyday driving conditions better than unvulcanized rubber bushings. If you are considering replacing your vehicle's rubber bushings, look for ones that have been vulcanized for the best performance.

For example, for rubber bushing with inner and outer pipes, the first step is to put the processed pipe into mold. Generally, the production of bushings with inner and outer pipes requires two molds to hold the pipes separately. If it is a complex product , The corresponding structure of the mold will be more complicated. After that, the worker sets the time and temperature required for vulcanization on the control panel of the machine, and the machine will automatically start working. The formulated rubber will be fed into the machine from the feeding port. When encountering high temperatures, the rubber will becomes soft due to heating and is injected into the steel pipes to make them adhere.

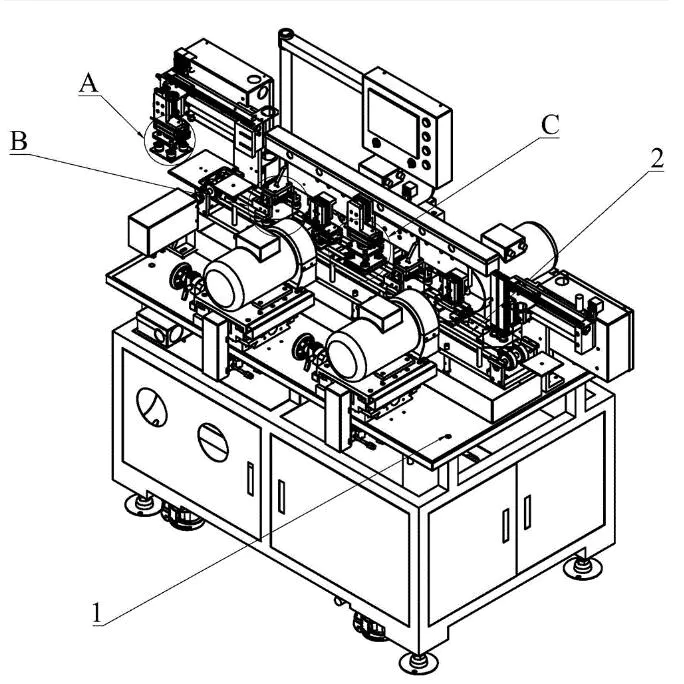

When the vulcanization time on the control panel returns to 0, the vulcanization process is completed. After the machine cools down, the mold will be sent out, and the worker will take out the bushing from the mold, and then repeat this process to continue production. The vulcanization process takes a long time, and the speed of production is related to the number of mold cavities. The new automated machine can accommodate larger molds and have higher productivity, which greatly improves the production efficiency of rubber bushings.

Nanchang GJ Bushing Factory orders surge this year. The stability and high efficiency of the machine can ensure delivery time, so that customers can receive high-quality products within a satisfactory time.

-

How are rubber bushings vulcanized

How are rubber bushings vulcanized -

aboutus

aboutus -

TOP SELLING Rubber Bushing ITEM 90389-14007

TOP SELLING Rubber Bushing ITEM 90389-14007 -

What Is The Function Of Engine Mount?

What Is The Function Of Engine Mount? -

Why Rubber Bushing needs chamfering process?

Why Rubber Bushing needs chamfering process? -

How to compare the bushing quality simply

How to compare the bushing quality simply -

Understanding Bushings

Understanding Bushings -

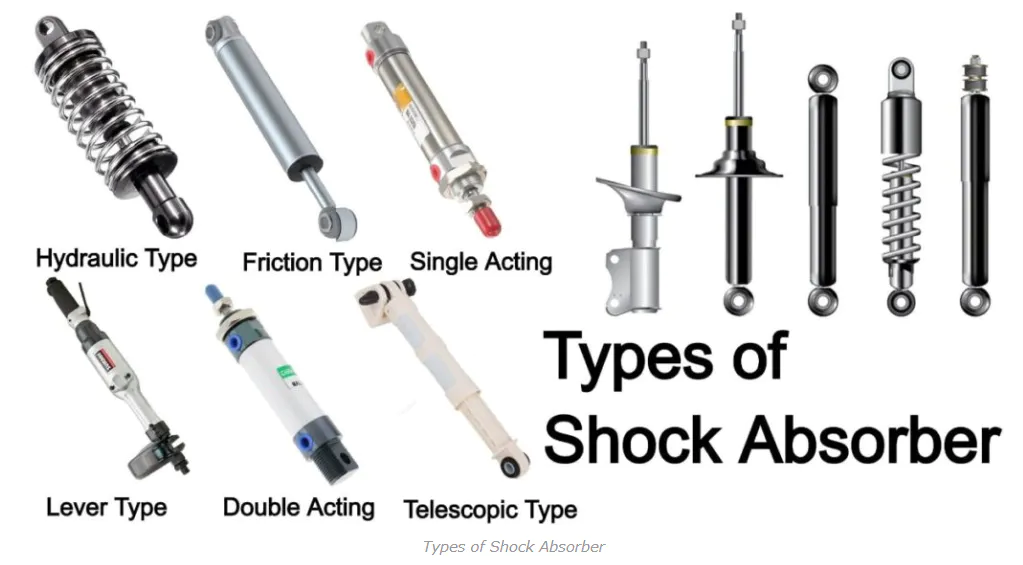

Function of Shock absorber

Function of Shock absorber -

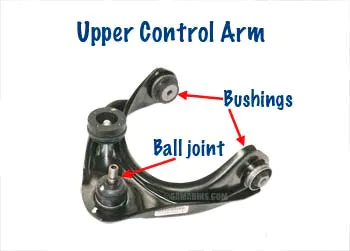

Control arms

Control arms -

Control Arm Process

Control Arm Process -

Road testing videos from our off-road vehicles client

Road testing videos from our off-road vehicles client -

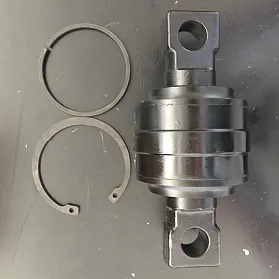

A hot-selling Pivot Bushing for Hendrickson and FREIGHTLINER Truck

A hot-selling Pivot Bushing for Hendrickson and FREIGHTLINER Truck -

Stabilizer link

Stabilizer link -

What are the benefits of modifying the shock absorber?

What are the benefits of modifying the shock absorber? -

Unpacking --- New Developed Samples

Unpacking --- New Developed Samples -

New Production Line of GJ BUSH

New Production Line of GJ BUSH -

The Importance of car shock absorber strut mount

The Importance of car shock absorber strut mount -

Our Products-GJ BUSH

Our Products-GJ BUSH -

GJ BUSH - Your Trusted Bimetal Bearings Manufacturer in China

GJ BUSH - Your Trusted Bimetal Bearings Manufacturer in China -

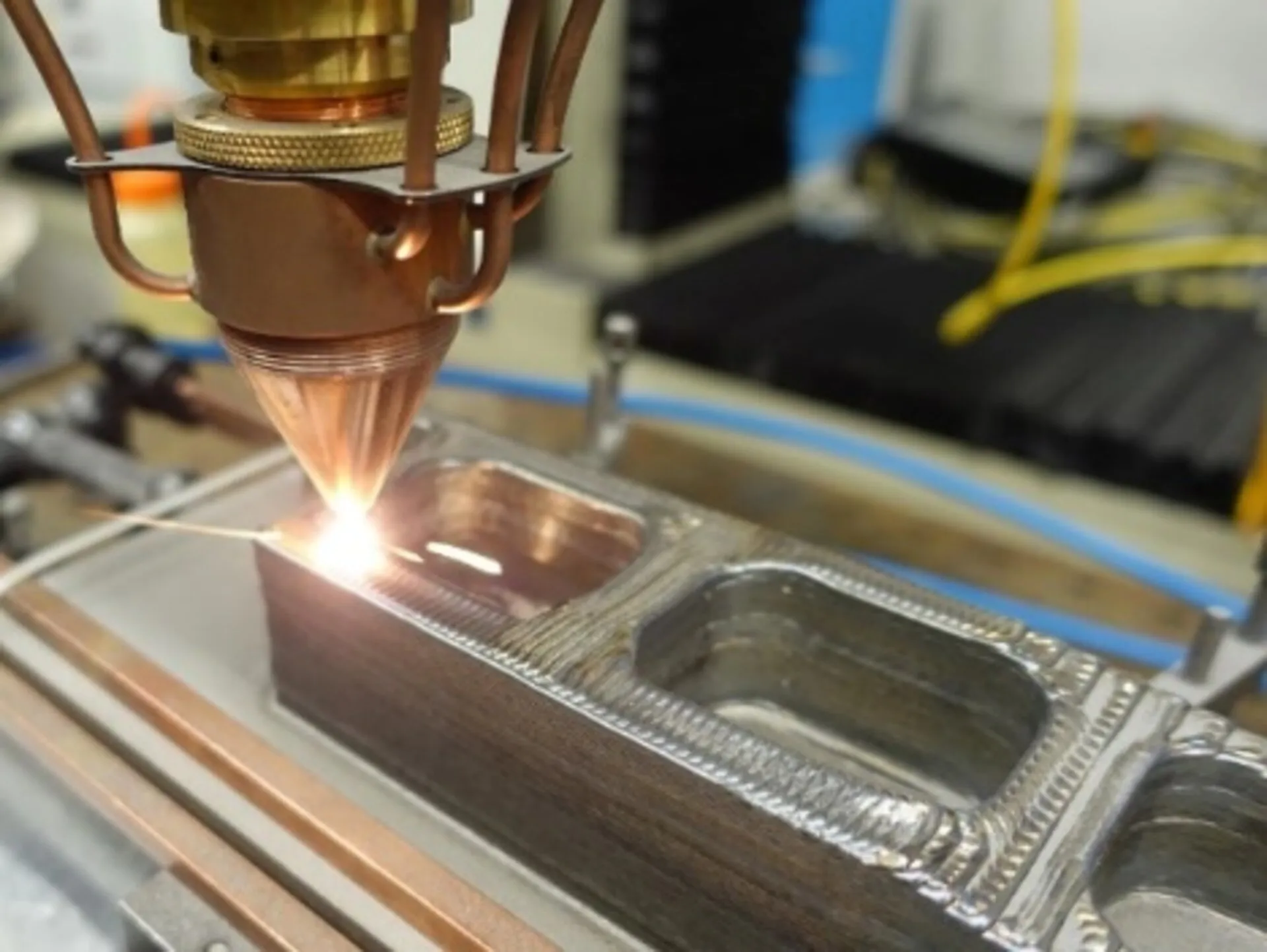

Laser printing help you make your own brand auto parts

Laser printing help you make your own brand auto parts -

Function of suspension system

Function of suspension system -

The processing of the steel pipe

The processing of the steel pipe -

Type of Measuring Gauge

Type of Measuring Gauge -

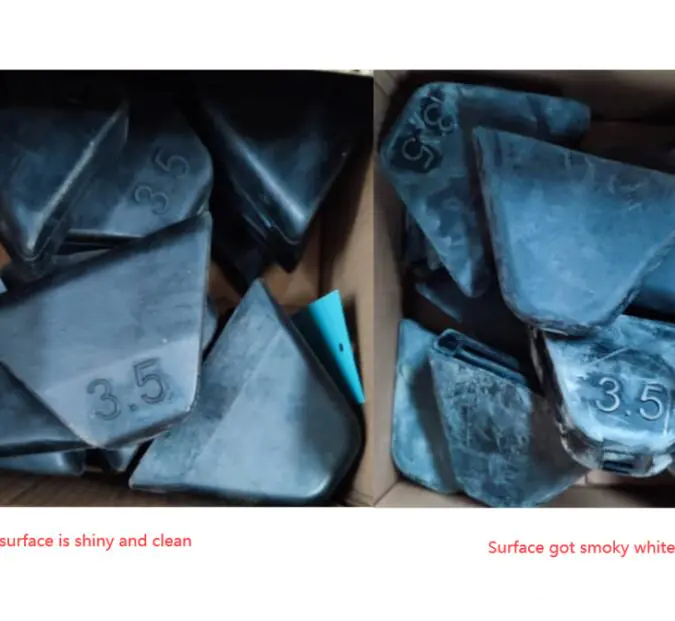

The cause of rubber blooming phenomenon and the influence

The cause of rubber blooming phenomenon and the influence -

Strut Mounts: Keeps your ride quiet and vibration free.

Strut Mounts: Keeps your ride quiet and vibration free. -

Knurling Process of Rubber Bushings

Knurling Process of Rubber Bushings -

What You Need to Know about Shock Absorbers ?

What You Need to Know about Shock Absorbers ? -

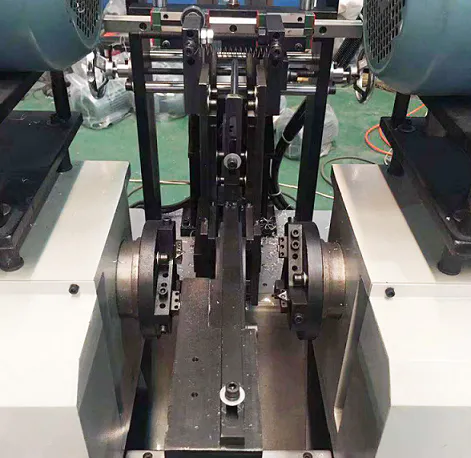

Fully automatic trimming machine for rubber bush

Fully automatic trimming machine for rubber bush -

Aluminum prices affect engine mount production

Aluminum prices affect engine mount production -

The importance of rubber mixing for rubber bushes

The importance of rubber mixing for rubber bushes -

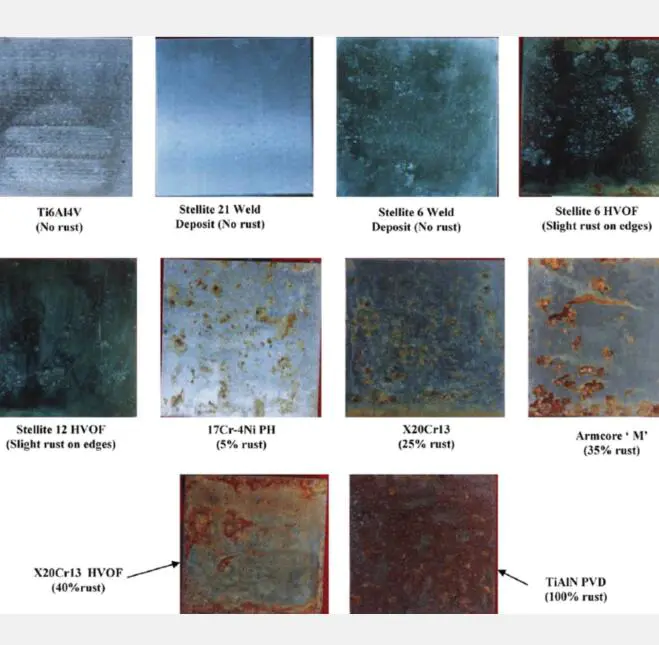

How to identify the corrosion resistance of bush?

How to identify the corrosion resistance of bush? -

How to Replace Car Shocks?

How to Replace Car Shocks? -

What are the production steps of bimetallic bushing

What are the production steps of bimetallic bushing -

Chamfering Machine

Chamfering Machine -

What is Shot Blasting? How does it work in bush production?

What is Shot Blasting? How does it work in bush production? -

Seamless Pipe Cutting Machine

Seamless Pipe Cutting Machine -

How to realize efficient management of warehouse through ERP system?

How to realize efficient management of warehouse through ERP system? -

Good news! The new factory is officially put into use

Good news! The new factory is officially put into use -

How to apply glue in rubber bush production

How to apply glue in rubber bush production -

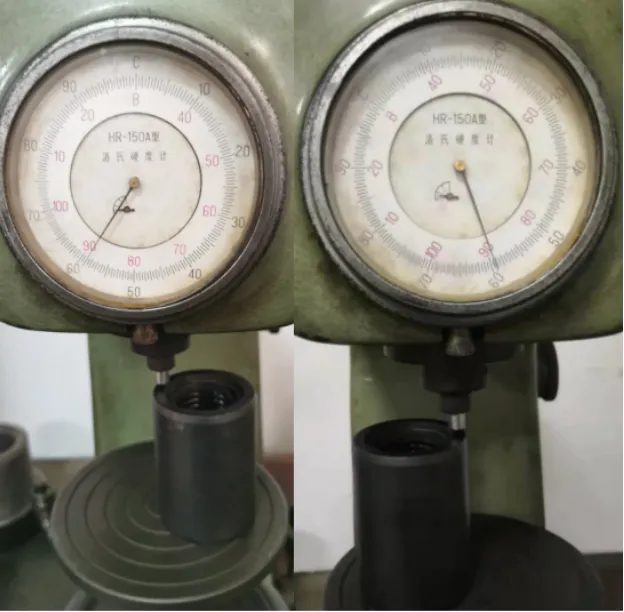

Metal Hardness And The Way To Test

Metal Hardness And The Way To Test -

GJ BUSH New phosphating line

GJ BUSH New phosphating line -

When and How to replace leaf spring bushing?

When and How to replace leaf spring bushing? -

How to replace Engine Mount?

How to replace Engine Mount? -

Shock absorber bushing

Shock absorber bushing -

OEM Leaf Spring Bushing Manufacturer

OEM Leaf Spring Bushing Manufacturer -

Carburization

Carburization -

New developed OEM quality Strut Mount

New developed OEM quality Strut Mount -

Chamfering Process

Chamfering Process -

Bimetal bushing & Cooper bushing

Bimetal bushing & Cooper bushing -

Original OEM supplier of Ford Transit

Original OEM supplier of Ford Transit -

Rubber Bushing Quality Inspection

Rubber Bushing Quality Inspection -

A revolution in the workshop

-

Cutting Pipes

Cutting Pipes -

You will know more about Nanchang Gangjiang Bush Factory

You will know more about Nanchang Gangjiang Bush Factory