The processing of the steel pipe

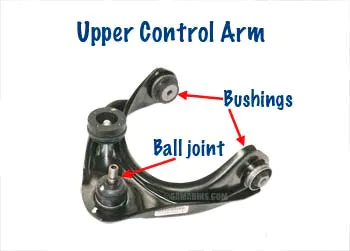

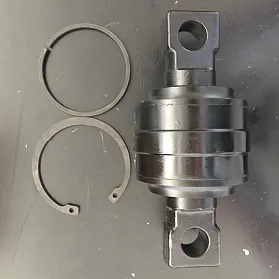

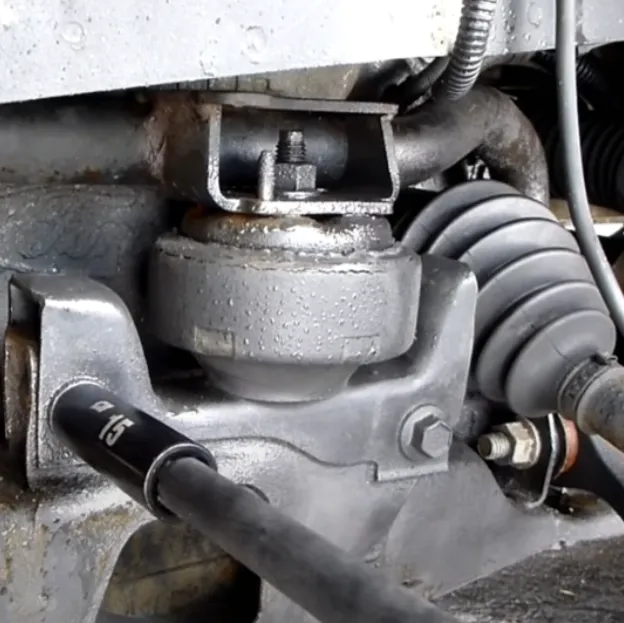

During the driving of the car, there will be a lot of waggle due to the mechanical vibration of the engine, the transmission itself, and the unevenness of the road surface. In order to suppress the waggle and isolate them from the body and the cab, many rubber and metal parts are installed on the car. Of the nearly 10,000 parts in a car, about 5% are rubber parts in various combinations, such as rubber suspension elements that connect the body to the engine and transmission, shock absorbers strut mount, suspension link rubber bushing etc.

The main function of these rubber-metal components in the suspension system is to make the suspension components move in a predetermined direction and transmit various forces on the one hand, and to suppress various vibrations and isolate various noises on the other hand. All in all, they are important for the steering, braking and driving stability of the vehicle, especially when driving on bumpy roads.

GJ bush is a professional automotive rubber metal components supplier, mainly focus on rubber bushing and rubber mount products. Today we will share the processing of the steel pipe to make a rubber bushing.

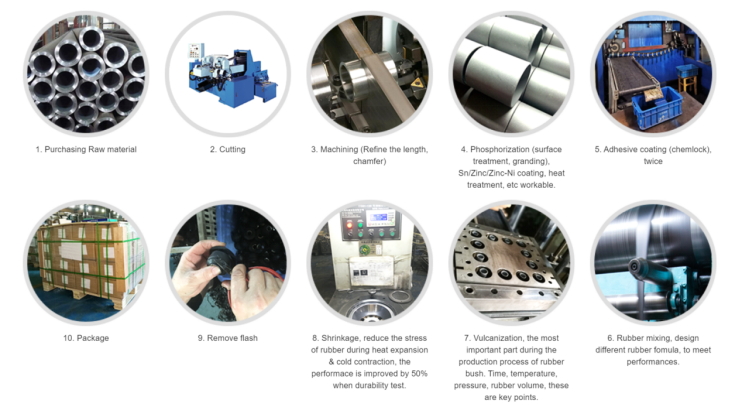

1. Purchasing raw material

2. Cutting pipe

Automatic pipe-cutting machine

3. Machining (Refine the length, chamfer)

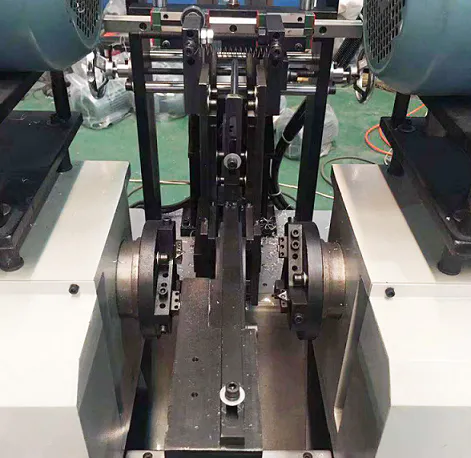

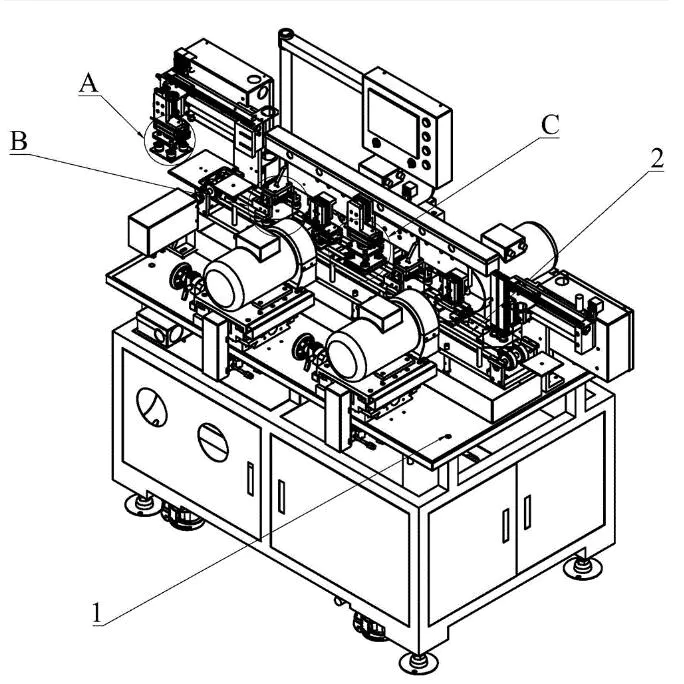

Automatic double end chamfering machine

CNC lathe

4. Phosphorization (Surface treatment, granding, heat treatment etc)

Our new factory have set up a set of automatic phosphorization production line.

5. Adhesive coating twice

6. Rubber mixing, design different rubber formula to meet customers’ performance.

7. Vulcanization, the most important part during the production process of rubber bush. Time, temperature, pressure, rubber volume, these are key points.

8. Shrinkage, reduce the stress of rubber during heat expansion & cold contraction, the performance is improved by 50% when durability test.

9. Remove flash

10. Package

-

The processing of the steel pipe

The processing of the steel pipe -

aboutus

aboutus -

TOP SELLING Rubber Bushing ITEM 90389-14007

TOP SELLING Rubber Bushing ITEM 90389-14007 -

How are rubber bushings vulcanized

How are rubber bushings vulcanized -

What Is The Function Of Engine Mount?

What Is The Function Of Engine Mount? -

Why Rubber Bushing needs chamfering process?

Why Rubber Bushing needs chamfering process? -

How to compare the bushing quality simply

How to compare the bushing quality simply -

Understanding Bushings

Understanding Bushings -

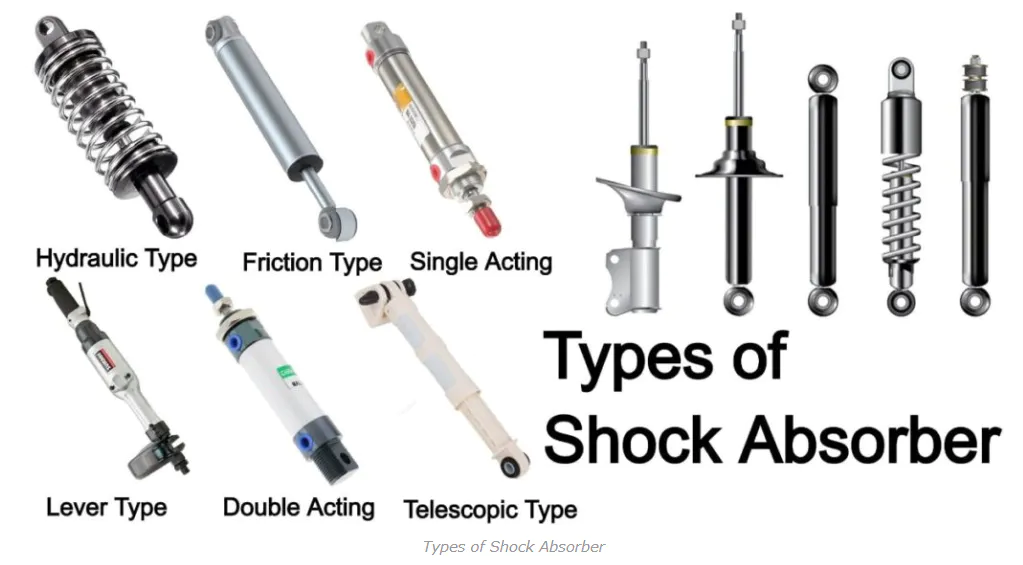

Function of Shock absorber

Function of Shock absorber -

Control arms

Control arms -

Control Arm Process

Control Arm Process -

Road testing videos from our off-road vehicles client

Road testing videos from our off-road vehicles client -

A hot-selling Pivot Bushing for Hendrickson and FREIGHTLINER Truck

A hot-selling Pivot Bushing for Hendrickson and FREIGHTLINER Truck -

Stabilizer link

Stabilizer link -

What are the benefits of modifying the shock absorber?

What are the benefits of modifying the shock absorber? -

Unpacking --- New Developed Samples

Unpacking --- New Developed Samples -

New Production Line of GJ BUSH

New Production Line of GJ BUSH -

The Importance of car shock absorber strut mount

The Importance of car shock absorber strut mount -

Our Products-GJ BUSH

Our Products-GJ BUSH -

GJ BUSH - Your Trusted Bimetal Bearings Manufacturer in China

GJ BUSH - Your Trusted Bimetal Bearings Manufacturer in China -

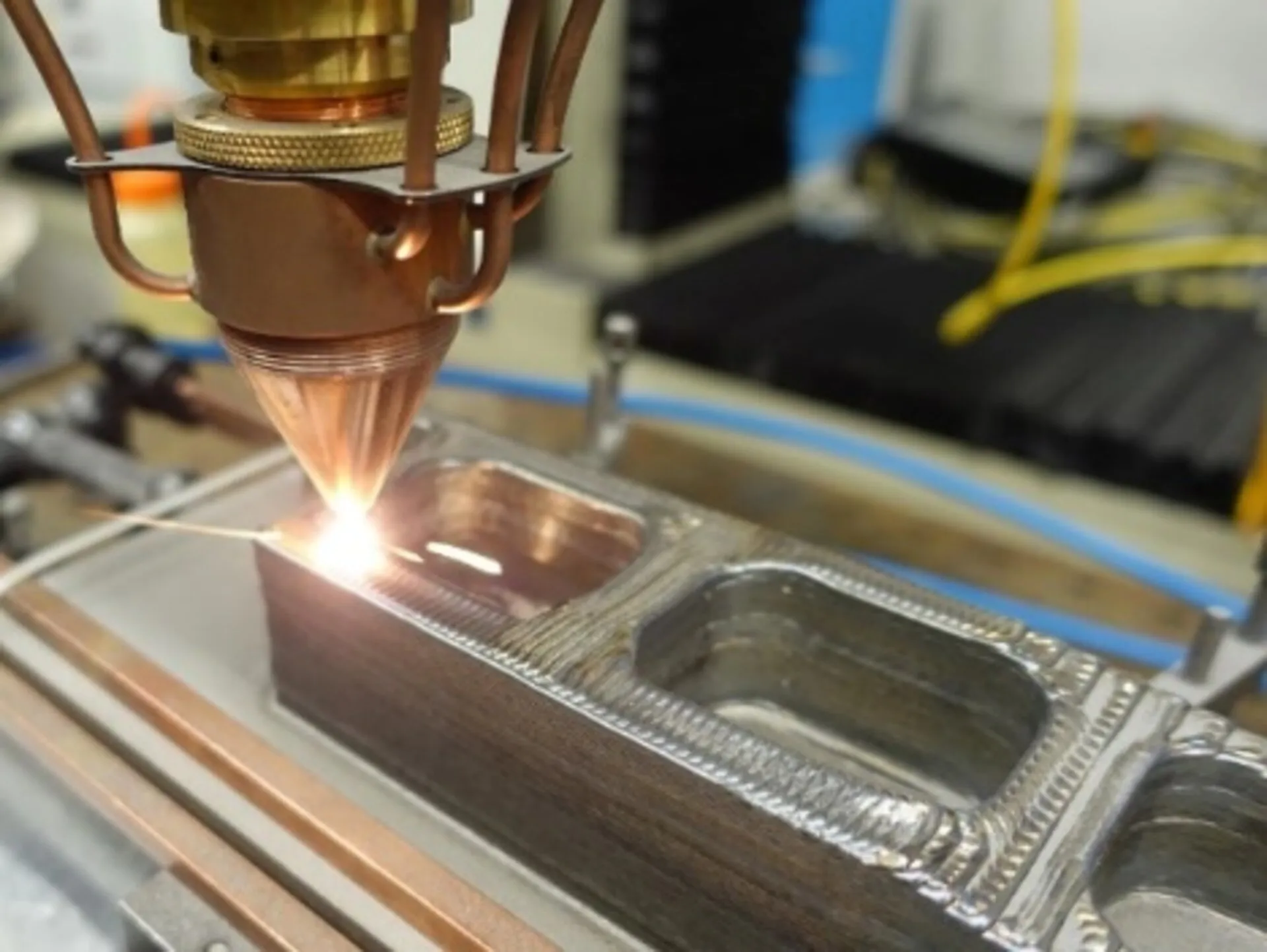

Laser printing help you make your own brand auto parts

Laser printing help you make your own brand auto parts -

Function of suspension system

Function of suspension system -

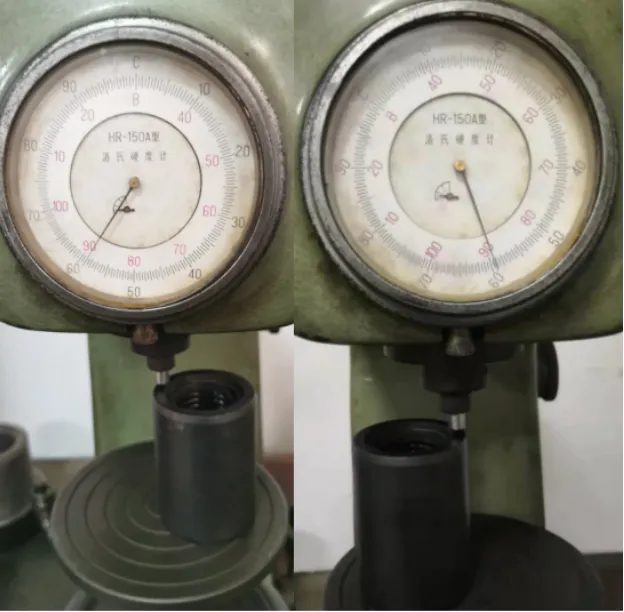

Type of Measuring Gauge

Type of Measuring Gauge -

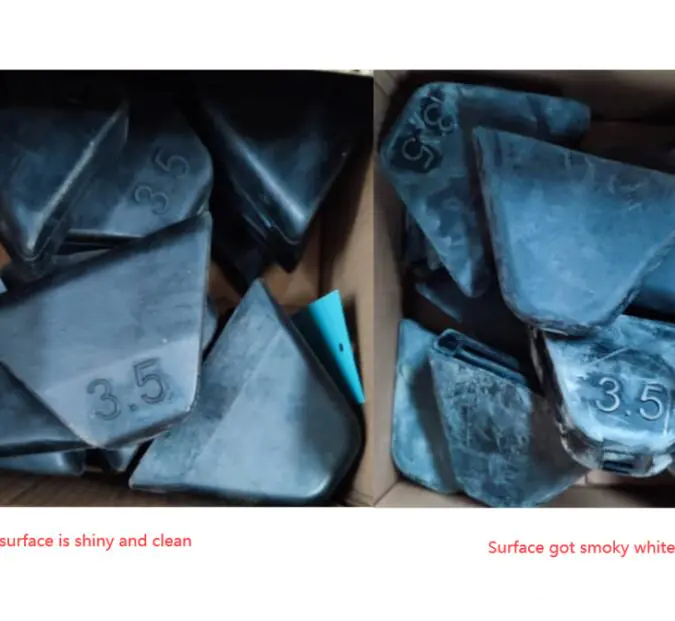

The cause of rubber blooming phenomenon and the influence

The cause of rubber blooming phenomenon and the influence -

Strut Mounts: Keeps your ride quiet and vibration free.

Strut Mounts: Keeps your ride quiet and vibration free. -

Knurling Process of Rubber Bushings

Knurling Process of Rubber Bushings -

What You Need to Know about Shock Absorbers ?

What You Need to Know about Shock Absorbers ? -

Fully automatic trimming machine for rubber bush

Fully automatic trimming machine for rubber bush -

Aluminum prices affect engine mount production

Aluminum prices affect engine mount production -

The importance of rubber mixing for rubber bushes

The importance of rubber mixing for rubber bushes -

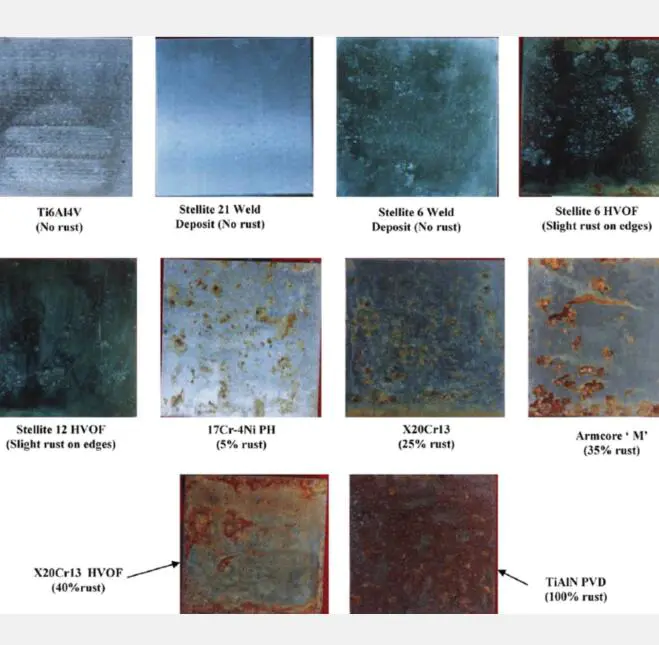

How to identify the corrosion resistance of bush?

How to identify the corrosion resistance of bush? -

How to Replace Car Shocks?

How to Replace Car Shocks? -

What are the production steps of bimetallic bushing

What are the production steps of bimetallic bushing -

Chamfering Machine

Chamfering Machine -

What is Shot Blasting? How does it work in bush production?

What is Shot Blasting? How does it work in bush production? -

Seamless Pipe Cutting Machine

Seamless Pipe Cutting Machine -

How to realize efficient management of warehouse through ERP system?

How to realize efficient management of warehouse through ERP system? -

Good news! The new factory is officially put into use

Good news! The new factory is officially put into use -

How to apply glue in rubber bush production

How to apply glue in rubber bush production -

Metal Hardness And The Way To Test

Metal Hardness And The Way To Test -

GJ BUSH New phosphating line

GJ BUSH New phosphating line -

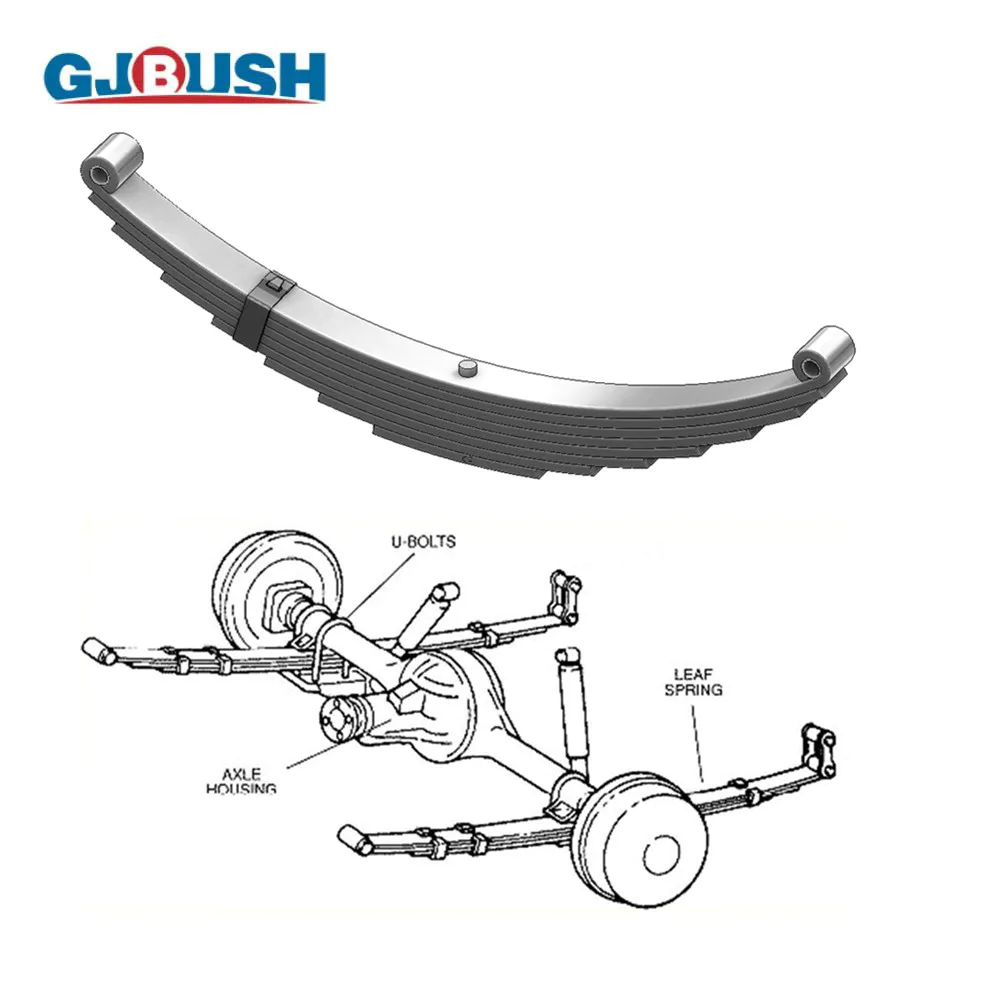

When and How to replace leaf spring bushing?

When and How to replace leaf spring bushing? -

How to replace Engine Mount?

How to replace Engine Mount? -

Shock absorber bushing

Shock absorber bushing -

OEM Leaf Spring Bushing Manufacturer

OEM Leaf Spring Bushing Manufacturer -

Carburization

Carburization -

New developed OEM quality Strut Mount

New developed OEM quality Strut Mount -

Chamfering Process

Chamfering Process -

Bimetal bushing & Cooper bushing

Bimetal bushing & Cooper bushing -

Original OEM supplier of Ford Transit

Original OEM supplier of Ford Transit -

Rubber Bushing Quality Inspection

Rubber Bushing Quality Inspection -

A revolution in the workshop

-

Cutting Pipes

Cutting Pipes -

You will know more about Nanchang Gangjiang Bush Factory

You will know more about Nanchang Gangjiang Bush Factory